What Is White Bitumen: Specifications + Applications

What is white bitumen? While we’re used to black bitumen, there is also a bitumen known as a waterproof membrane. This bitumen has strong waterproofing properties and shares many characteristics with black bitumen, such as viscosity and adhesiveness. Because of this, it has various applications, including construction, waterproofing membranes, plastic and paint production, pipe insulation, and asphalt production. So, if you are a civil engineer or a researcher interested in learning more about white bitumen and its uses, read this article from Iran ETrade.

What is white bitumen?

White bitumen has properties and characteristics similar to black and refined bitumen and has similar applications.

White bitumen—also known as camphor bitumen, albokarbon, or naphthalene—is a solid aromatic hydrocarbon derived from coal. It has high adhesiveness, good tensile strength, and strong waterproofing ability.

But what is the history of white bitumen, and when exactly was it discovered?

History of White Bitumen

Although white bitumen was discovered over 200 years ago, its use has recently become more popular due to the declining availability of petroleum-based bitumen.

When was white bitumen discovered? In 1819, when chemists were distilling coal identified white bitumen for the first time. In the following decades, scientists such as John Kidd, Michael Faraday, and Emil Erlenmeyer studied its properties and determined its chemical structure.

Therefore, it was in the early to mid-19th century that white bitumen and its uses gradually became known worldwide. However, do you know what white bitumen is composed of?

Composition of White Bitumen

What are the structure and properties of white bitumen? Due to its unique composition, white bitumen contains specific components, additives, and physical characteristics, including:

Chemical Composition

What is the chemical structure of white bitumen? Initially, white bitumen is derived from regular black bitumen. But its color is altered from dark to white by undergoing specific processes.

To achieve this transformation, manufacturers add light-colored pigments such as limestone or titanium dioxide. These additives give the bitumen a lighter color while preserving its essential properties.

Additives

What types of additives are used in white bitumen?

Manufacturers may add polymers to white bitumen to enhance its flexibility and prevent degradation, as well as UV stabilizers to protect it from sunlight. These additives improve its durability and overall performance.

Physical Properties

What are the physical characteristics of white bitumen? White bitumen has a light color that reflects sunlight and absorbs less heat.

It also has high adhesiveness, good flexibility, and resistance to weather conditions, making it ideal for construction uses.

Advantages of White Bitumen

What are the benefits of using white bitumen? By using this material, you can gain the following advantages:

- Seamless, lightweight structure

- Excellent adhesiveness

- Insoluble in water and highly resistant to moisture

- Resistant to temperature changes

- High tensile strength and elasticity

- Unique and aesthetically pleasing appearance, giving it more specialized uses than black bitumen

- Since white bitumen is a single-component material, it doesn’t need to be mixed with other substances for use.

Disadvantages of White Bitumen

What are the disadvantages of using white bitumen? Although using white bitumen has several advantages, like any material, it also comes with some drawbacks:

- Higher initial production cost compared to traditional bitumen

- May require maintenance or repairs over time

- Proper application requires expertise to achieve the best results

Applications of White Bitumen

What is white bitumen used for? Thanks to its physical properties and chemical structure, white bitumen has a variety of uses, including:

1. Production of White Waterproofing Membranes

Why is white bitumen used to produce white waterproofing membranes? Due to its lightweight nature and low light absorption, white bitumen is an excellent material for making waterproof membranes.

It’s also water-resistant and easy to install. However, it may not be the most efficient choice for areas with extreme temperature fluctuations.

2. Manufacturing Plastics and Paints

What is white bitumen used in producing plastics and paints? Due to its single-component nature, white bitumen is easy to work with in manufacturing processes and has many uses in the production of various plastics and paints.

3. Asphalt Production

How is white bitumen usage in asphalt production? White bitumen is suitable for producing asphalt because it creates a bright, durable surface from the start. This removes the need to paint regular asphalt and saves both time and cost.

4. Pipe Insulation with White Bitumen

What is white bitumen use for pipe insulation? White bitumen is well-suited for insulating pipes because you can apply it on its own without needing to mix it.

It doesn’t absorb sunlight, resists moisture, and its ability to be colored gives it versatile applications in both industry and construction. All these features make it a great choice for pipe insulation.

5. Pest Control and Disinfection

What is white bitumen use for pest control and disinfection? White bitumen is soluble in methanol and is usable for disinfecting and pest control. It’s also commonly applied to prevent moth damage in carpets.

6. Tree Insulation with White Bitumen

What is white bitumen usage for tree insulation? As mentioned earlier, white bitumen has disinfecting and insect-repelling properties.

Gardeners can use it to protect trees from insect damage, moisture, and sunlight which helps to preserve tree health and bark integrity.

7. Waterproofing Insulation with White Bitumen

What white bitumen use for waterproofing insulation? Due to its high adhesiveness and flexibility, white bitumen forms a strong barrier against water penetration. Therefore, it has many uses in waterproofing foundations, tunnels, and basements.

Methods of Using White Bitumen

What are the methods of using white bitumen? The methods of using white bitumen vary depending on its use.

For example, in asphalt concrete production, manufacturers mix white bitumen with materials like gilsonite, bituminous rocks, sand, and gravel. They then heat this mixture and compact it to produce white asphalt concrete. The use of this concrete on surfaces can be done by using standard equipment.

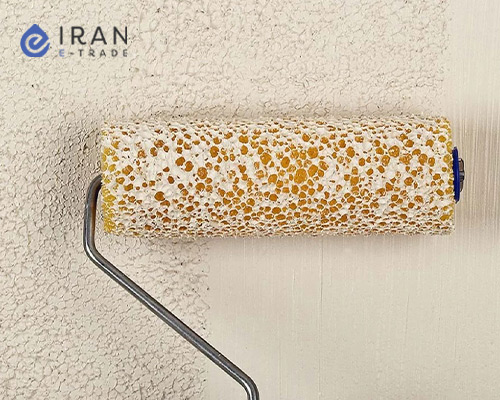

Spraying

What is the method of spraying white bitumen? For waterproofing roofs and surfaces with white bitumen spray, the surface has to be cleaned and prepared. Then, the workers apply white bitumen in multiple layers using a roller or brush.

In agriculture, farmers dilute white bitumen emulsion with water and spray it to control dust or stabilize soil.

Maintenance and Lifespan of White Bitumen

Which is the best way to maintain white bitumen and how long is its lifespan? To increase the durability of white bitumen, you should regularly clean it to prevent excessive dirt buildup. Additionally, you should immediately repair any damage to the surface to extend its lifespan.

Keep in mind that Factors like weather conditions, heavy traffic and improper installation can affect the lifespan of white bitumen. However, proper maintenance, use of high-quality materials, and professional application help to enhance its durability.

Environmental Impact of White Bitumen

What are the eco-friendly alternatives and methods for recycling and disposal of white bitumen? Eco-friendly alternatives to white bitumen are being developed to reduce its harmful environmental impacts while maintaining similar performance and durability.

Additionally, proper recycling and disposal of white bitumen prevents environmental damage. Recycling allows for the reuse of materials, while proper disposal helps manage waste more effectively.

Frequently Asked Questions About White Bitumen

Here are some of the most commonly asked questions about white bitumen:

What Are the Other Names for White Bitumen?

Other names for white bitumen include naphthalene, albolabrin, and camphor.

What Is the Difference Between White and Black Bitumen?

White bitumen is derived from coal, while black bitumen is produced from petroleum, a resource that is gradually depleting.

What Is the Difference in the Uses of White and Black Bitumen?

While both are used in road construction and waterproofing, white bitumen also has uses in disinfection and pest control, which black bitumen does not.

How Long Does White Bitumen Last on Surfaces?

White bitumen typically lasts for several years on surfaces, provided it is properly applied and well maintained.

How to Maintain White Bitumen?

To maintain white bitumen, clean its surface regularly using soft tools. Avoid impacts and scratches, and place pads or rugs under heavy objects to protect it. Also, keep it away from acidic or abrasive chemicals.

reference: roofingcontractor

- Bitumen Suitable for Hot Climates: Benefits + Key Technical Tips

- How to Use Nano Bitumen: Properties & Applications + Method...

- Petroleum Products and Petroleum Derivatives: Introduction + Uses

- Oil Refineries in Iran: Complete List + Comparison

- Gasoline Producing Refineries in Iran: 12 Major Refineries

- Largest Oil Producers in the World: The Top 13 Countries...