Bitumen Transportation Methods: The Latest Urban and Export Bitumen Transport Techniques

Bitumen Transportation Methods include bulk thermal tankers, metal drums, bitumen tankers, pipelines, rail transport, bitumen bags (Bitubag), and specialized containers. Each method is selected based on the type of bitumen, climate conditions, distance from the destination, and project requirements. Consequently, choosing the right bitumen transport method plays a key role in preserving its quality, reducing costs, and complying with safety and environmental standards. Therefore, in this following article from Iran E-Trade blog, a specialized source for bitumen price inquiries, we introduce various methods of urban and export bitumen transportation.

How is bitumen transported?

Bitumen Transportation Methods play a key role in the safe and efficient transfer of bitumen from the production site to construction projects. By selecting the appropriate method, it is possible to optimize bitumen quality, costs, and project execution time.

Due to its sticky nature and high temperature, methods of bitumen transportation must be highly precise and they require specialized equipment. Common methods include the use of drums, tankers, specialized containers, pipelines, hot bitumen ships, and rail transport. Furthermore, each is selected based on the volume, distance, and type of bitumen.

Bitumen Transportation Methods

Bitumen transportation methods are different based on environmental conditions, distance, and intended use. These methods are different and specialized, which we will explore more below:

1. Bitumen Drums

One of the traditional bitumen transportation methods is using metal drums. These drums are typically made of durable steel and have various sizes.

Using drums allows for easy transportation and storage. However, compared to more modern methods, they are less efficient. Also, drums require cleaning, and the workers often cannot fully empty the bitumen from them.

2. Hot Bitumen Ships as a Method of Bulk Bitumen Transportation

Hot Bitumen Ships can transport liquid bitumen over long distances. These ships are equipped with thermal tanks that maintain the temperature of bitumen at around 250°C. Therefore, this method is suitable for exporting large volumes of bitumen.

3. Bitumen Containers

Bitumen containers have proper insulation and heating systems that allow for safe and hassle-free transportation of bitumen.

In this way, bitumen is stored in liquid form inside these containers and is fully discharged by using specialized pumps.

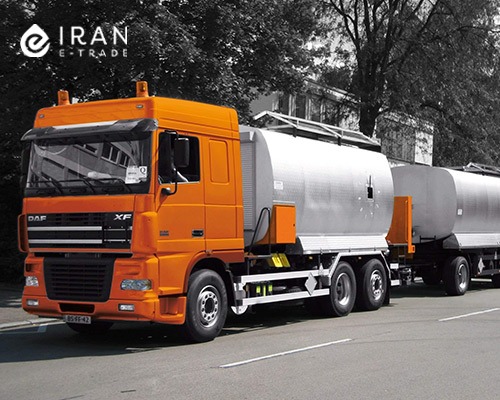

4. Bitumen Tankers as common Bitumen Transportation Methods

One of the most common bitumen transportation methods is the use of road tankers with insulated walls that are equipped with electric or thermal heaters. These tankers maintain the bitumen’s temperature and can distribute it to construction projects across various regions.

5. Pipelines

In some refineries, the manufacturers transport hot bitumen through heated pipelines. This method is cost-effective, safe, and fast for internal transfers, but it is only suitable for specific distances and industrial settings.

6. Rail Transport as Bitumen Transportation Methods

Tank wagons with internal heating systems transport bitumen by rail. This is the most suitable solution for bulk bitumen transport over long and hard-to-reach distances and enables the continuous movement of large volumes of bitumen.

Bitumen Transportation Methods In Urban Areas

The urban bitumen transportation includes using small insulated tankers, specialized trucks, and dedicated professional services.

Bitumen transportation methods in urban areas require careful planning due to traffic, short distances, and high sensitivity to safety and pollution.

Therefore, in such settings, smaller vehicles with proper insulation and heating systems—such as small tankers and trucks—can keep bitumen at the right temperature and deliver it safely to the usage site.

1. Small Bitumen Tankers

These tankers are usually mounted on light trucks or heavy-duty pickups and have a limited capacity ranging from 1 to 5 tons. They also have heating systems with electric elements or diesel burners to maintain the bitumen temperature between 140°C and 180°C.

2. Urban Bitumen Transport Method: Trucks

One of bitumen transportation methods is using specialized trucks, such as dump trucks or cargo trucks fitted with mounted tanks. Specifically, These tanks are usually double-walled and insulated and have internal heating systems to maintain the bitumen at the desired temperatures.

However, trucks have a medium capacity and are generally suitable for transporting bitumen from the factory to construction sites within the city. Therefore, in this method, ensuring safety and preventing leaks or combustion is critically important.

3. Use of Transport Services

Many construction companies and municipalities rely on specialized bitumen transport services to reduce equipment maintenance costs and improve efficiency.

In particular, these services provide equipped tankers, trained drivers, and route planning, which help minimize risks and enhance the accuracy and safety of bitumen transport.

Importance of Choosing the Right Route for Urban Bitumen Transport

Selecting the right route for urban bitumen transport is crucial for bitumen safety, time efficiency, fuel consumption, and maintaining the bitumen’s temperature. Routes with minimal stops, easy access, and low traffic help keep the bitumen at standard temperatures and reduce the risk of accidents or leaks.

Export Bitumen Transportation Methods

The export methods of bitumen transportation include sea, road, rail, and, in rare cases, air transport and are each selected based on the type of bitumen and its destination.

Accordingly, for export, bitumen transportation methods have to be in a way to handle bulk or packaged shipments while preserving bitumen quality throughout the journey.

Also, the type of bitumen, country of destination, and port or border infrastructure play key roles in selecting the transport method. Furthermore, Sea, road, and rail transport are the most common methods for bitumen export.

1. Methods of Bitumen Transportation: Sea Transport

In this method, the workers load bitumen into insulated tanks with steam or oil heaters on specialized ships. Then, the bitumen’s temperature is maintained throughout the journey to prevent its hardening. Therefore, sea transport is highly economical and efficient for exporting large volumes over long distances.

2. Road Transport

For land export of bitumen to neighbouring countries, bitumen manufacturers use insulated tankers equipped with heating systems. These tankers typically can carry up to 25 tons and can maintain the bitumen at the proper temperature for several hours during transport.

3. Rail Transport Methods for Bitumen

Specialized tank wagons with thermal insulation and internal heating systems can transport large volumes of bitumen between cities or to border points. This method is cost-effective, sustainable, and safe, making it highly efficient for long routes with suitable rail infrastructure.

4. Air Transport of Bitumen

Air transport of bitumen is extremely rare and is typically reserved for emergencies or special projects in hard-to-reach areas.

In such cases, the workers transport bitumen in special packages or heat-resistant containers. Due to its heavy weight and the need to maintain temperature, this method is very costly and economically inefficient. However, it is occasionally useful in military or emergency operations.

The Importance of Bitumen Packaging for Transport and Export

Bitumen is a highly viscous material with a low melting point and is very sensitive to temperature changes. Therefore, proper packaging plays a crucial role in maintaining its quality, ensuring its safety, and facilitating ease of transport on international routes.

Standard packaging—such as metal drums, polypropylene bags, or IBC containers—prevents leakage, environmental contamination, and material loss. Therefore, in bitumen exports, complying with international bitumen packaging standards (such as ASTM or EN) is essential for entering global markets and obtaining customs clearance.

Considerations for International Bitumen Transportation

In international bitumen transport, adherence to technical, environmental, and legal requirements is of utmost importance. Reputable transport companies typically handle all these aspects with a high level of expertise and professionalism.

To prevent changes in viscosity and pipeline blockage, bitumen must be maintained at the proper temperature—typically between 120°C and 180°C for bulk bitumen. Additionally, selecting suitable transport equipment, such as insulated tankers, and obtaining certificates for transporting hazardous materials are essential requirements.

Moreover, compliance with the regulations of destination countries—such as environmental restrictions or specific packaging requirements—directly affects the export process.

Types of Bitumen Transport Vehicles

Transporting bitumen—whether in bulk or packaged form—requires specialized vehicles. Depending on the type of bitumen and the transport distance, bitumen transport vehicles have several main types:

1. Specialized Bitumen Tankers

One of the most common bitumen transportation methods is tanker trucks. These tankers have systems to maintain the bitumen’s temperature throughout the journey and they usually can transport large quantities of liquid bitumen.

2. Heating Trailers

The heating trailers for bitumen transport are suitable for long-distance routes and play a crucial role in maintaining the product’s temperature. These trailers have insulated tanks and internal heating systems that are typically powered by diesel burners or hot oil coils.

Furthermore, they have digital temperature control, safety valves, and rapid discharge systems which ensure high efficiency and reduced energy loss during transport.

3. Tanker Trucks

One of bitumen transportation methods over short to medium land distances is using tanker trucks. Their capacity varies and is selected based on the type of bitumen (petroleum-based or modified) and route conditions. A key feature of these trucks is their increased safety against leaks and adjustable temperature control.

4. Bitumen Drum Transport Vehicles

Packaged bitumen in metal or plastic drums requires vehicles capable of safely and efficiently handling the weight and shape of these drums. Bitumen drum transport vehicles typically feature reinforced containers and securing systems to prevent the drums from leaking during transit.

Features of Bitumen Transport Tankers

Bitumen transport tankers’ design must be by international standards to ensure not only bitumen’s quality and safety but also its full efficiency delivery without damaging its composition.

Heating System

Bitumen tankers have direct or indirect heating systems that use steam coils, thermal oil, or diesel burners to maintain the bitumen temperature between 130°C and 180°C.

These systems use digital controllers to regulate bitumen’s temperature, preventing increased viscosity or blockages. Therefore, the heating design must ensure bitumen’s uniform, safe heating with high thermal efficiency.

Proper Insulation

To prevent heat loss and reduce energy consumption, precise thermal insulation in bitumen tankers is crucial. Typically, layers of rock wool, polyurethane foam, or fibreglass coated with aluminium are used to minimize heat transfer from the environment in these tankers.

Also, since tankers are among the most common bitumen transportation methods, proper insulation is especially important for their effectiveness.

Resistant to Temperature and Pressure

The body of bitumen tankers must be made from heat- and pressure-resistant alloys, such as reinforced carbon (stainless) steel. This durability is essential to withstand steam pressure at high temperatures and prevent deformation of the tank.

High Capacity

Standard bitumen tankers typically have a capacity ranging from 15,000 to 35,000 litres and are suitable for land or sea export. High capacity increases transport efficiency, reduces operational costs, and optimizes loading and unloading times.

Equipped with Pumping System

The bitumen pumping system is a vital component of tankers that enables safe, fast, and continuous discharge of the bitumen. This system typically includes high-pressure gear or screw pumps designed to withstand high temperatures and the bitumen’s high viscosity.

Precise Monitoring and Control of Temperature and Pressure

Modern tankers have sensors and digital monitors to continuously track bitumen temperature and internal pressure. Moreover, advanced control systems provide real-time information to the driver or operator and issue necessary alerts in case of any irregularities.

Leak Resistant

To prevent bitumen leakage at high temperatures, tanks must have precise welding, heat-resistant gaskets, and secure valves. For this purpose, the use of double flanges, safety valves, and sealing materials such as Teflon and graphite helps block any penetration or leakage of bitumen.

Ease of Loading and Unloading of Bitumen

The design of the inlet and outlet ports in tankers should enable fast, safe, and thermally efficient bitumen loading and unloading processes.

Using automatic pumping systems, large valves, thermal filters, and quick coupling connections significantly improves bitumen transportation efficiency.

Equipped with Ventilation System

Having a ventilation or vapour release system in bitumen tankers prevents excessive internal pressure buildup. These systems usually include safety valves and heat-resistant vent pipes that help discharge volatile vapours safely.

Corrosion-Resistant Coating

The interior surfaces of bitumen tankers must be coated with high-temperature resistant anti-corrosion materials, such as modified epoxy or liquid ceramic, to protect against damage caused by the chemical properties of bitumen.

Given the widespread use of tankers as one of the common bitumen transportation methods, meeting this requirement is especially important.

The Importance of Bitumen Transportation Methods and Key Considerations

Due to its unique physical properties of bitumen—such as high viscosity and temperature sensitivity—bitumen transportation requires precise conditions and specialized equipment. Therefore, there are very important factors to consider:

Maintaining Bitumen Quality and Properties

Bitumen has to be transported under conditions that prevent any change in its physical and chemical properties. Exposure to air, excessive temperature fluctuations, or contamination with foreign substances can reduce adhesion, lower the softening point, or increase oxidation.

Protecting the Environment

Bitumen is a petroleum-based and potentially polluting material, so its transportation has to comply with environmental regulations.

Therefore, using leak-resistant tanks, proper ventilation systems, and adhering to international hazardous materials transport regulations (such as ADR and IMDG) is essential to protect the environment.

Safety Considerations in All Bitumen Transportation Methods

Safety in bitumen transport means preventing fire, explosion, burns, and leaks.

This is because the high temperature of bitumen, its chemical composition, and flammable vapours require the use of secure equipment, safety valves, complete insulation, and warning systems.

Considerations of Efficiency

Efficiency in bitumen transportation refers to the system’s ability to deliver the material safely, quickly, and at minimal cost.

Therefore, using high-capacity tankers, properly designed loading and unloading routes, and precise transport scheduling all contribute to enhancing operational productivity.

Bitumen Transport Companies

Specialized bitumen transport companies must hold legal permits, operate ships equipped with heated tankers, employ trained personnel, and have proper insurance coverage.

These companies should also comply with international safety, environmental, and quality standards and provide precise control systems to monitor temperature, pressure, and tank conditions.

Why Must Bitumen Be Transported at High Temperatures?

At ambient temperatures, bitumen is very thick or even solid and only becomes fluid at high temperatures—usually between 130°C and 180°C. Consequently, this fluidity is essential for bitumen pumping, unloading, and transportation.

Failure to maintain these temperatures causes bitumen to harden, leading to pipeline blockages and equipment damage. Therefore, transporting bitumen at high temperatures is a fundamental requirement for safety and efficiency in bitumen transportation methods.

Frequently Asked Questions Regarding Bitumen Transportation Methods

In this section, we address the most common questions related to bitumen transport methods:

What Are the Best Methods of Bitumen Transportation?

The most important factors in choosing bitumen transport methods are the project type, distance, and volume. Generally, insulated thermal tankers are very suitable for bulk transport, while packaged drums are more popular for short-term exports.

What Is the Most Common Method for Exporting Bitumen?

The most common bitumen transportation methods in exports include transportation in metal drums, heated bulk tankers, and packaging in bitumen bags (Bitubag).

- Petroleum Products and Petroleum Derivatives: Introduction + Uses

- Oil Refineries in Iran: Complete List + Comparison

- Gasoline Producing Refineries in Iran: 12 Major Refineries

- Largest Oil Producers in the World: The Top 13 Countries...

- The Largest Bitumen Refineries In The World: Top 20 Refineries...

- What Is An Oil Lubricant: Types, Applications + Production