What Is Refinery Bitumen: Specifications and Applications

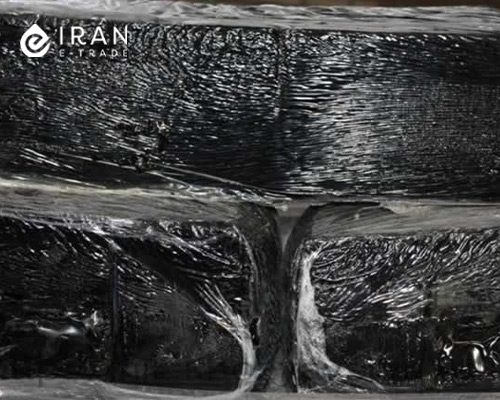

What is refinery bitumen, and what role does it play in various industries? One of the key products obtained from crude oil distillation is refinery bitumen, also known as refinery bitumen. This type of bitumen, available in semi-solid or liquid form, has many uses in construction and road-building projects due to its stable physical and chemical properties. It also plays a crucial role in asphalt production, waterproofing, and the manufacture of moisture-insulating materials. Therefore, in this article from the Iran ETrade blog, a specialised source for bitumen pricing, we will provide a comprehensive overview of this type of bitumen and its applications.

Types of Bitumen

Bitumen is a black, sticky, and viscous hydrocarbon material that bitumen manufacturers derive from the processing of crude oil. It comes in various types and is considered one of the best options due to its high thermal resistance and excellent environmental compatibility.

Bitumen is a heavy, sticky hydrocarbon substance produced naturally or through crude oil refining processes. Therefore, to understand what refinery bitumen is, its different types and properties are a crucial foundation for you to make the right choice in engineering projects.

1. What is Refinery Bitumen?

One of the most important types of bitumen is refinery bitumen (refined bitumen), which bitumen manufacturers produce through the vacuum distillation of crude oil. In this process, the lighter oil fractions are separated, leaving behind the heavier residue in the form of bitumen.

Types of refinery bitumen are classified based on their physical properties and penetration grade.

Refinery bitumen is solid at ambient temperature but becomes fluid at high temperatures, making it suitable for applications such as asphalt production and waterproof coatings.

The quality standards for refinery bitumen are defined by specifications such as ASTM D946 or EN 12591.

2. Natural Bitumen

As the name suggests, natural bitumen (also known as Gilsonite) is found naturally in underground or surface deposits.

This type of bitumen forms naturally over time as the lighter components of crude oil evaporate, leaving behind a material with a high percentage of asphaltenes and minerals. It is worth noting that Iranian Gilsonite is considered one of the valuable resources in this field.

3. Blown or Oxidised Bitumen

When we ask the question of “what is refinery bitumen?”, it’s important to highlight blown bitumen (also known as oxidised bitumen) as a key category. The bitumen manufacturers produce blown bitumen by blowing hot air through refinery bitumen under controlled conditions.

This process increases the molecular weight, raises the softening point, and lowers the penetration grade of the bitumen. Furthermore, blown bitumen has a thermoplastic-like structure; it is hard and brittle at normal temperatures but becomes viscous at high temperatures.

4. Cutback Bitumen

A mixture of base bitumen and volatile solvents such as naphtha, gasoline, or kerosene comprises cutback bitumen.

Adding the solvent reduces the viscosity of the bitumen, allowing it to be applicable at ambient temperatures. After application, the solvent gradually evaporates, leaving the original bitumen behind.

What is Refinery Bitumen Production Process?

Bitumen manufacturers produce refinery bitumen from the distillation of crude oil in atmospheric and vacuum distillation towers. Then, they process it through air blowing or blending techniques to enhance its properties such as thermal resistance and adhesion.

What is refinery bitumen, and how is it produced? The production process of refinery bitumen involves precise stages that determine its molecular structure, viscosity, softening point, thermal stability, and other performance characteristics.

The main industrial methods for producing refinery bitumen include the direct distillation process, the air blowing process, and the blending or mixing process, which we will discuss below:

1. Direct Distillation Process

This is the most fundamental and initial step in the production of refinery bitumen. The bitumen manufacturers first heat crude oil in an atmospheric distillation tower. Then, lighter components such as gases, gasoline, kerosene, and diesel are vaporised and separated at lower temperatures.

The manufacturers transfer the residue from the atmospheric distillation tower, which has high viscosity, to the vacuum distillation tower. Here, heavier intermediate components such as lubricating oils are separated without thermal cracking.

Finally, what remains at the bottom of this tower is the main feedstock for producing refinery bitumen.

2. Air Blowing Process

In this method, the manufacturers expose base bitumen derived from distillation to hot air under controlled conditions. Then the resulting bitumen has improved physical properties. In this way, Oxygen in the air reacts with the active components of the bitumen, and increases its molecular weight and viscosity.

This process increases bitumen’s softening point, decreases its penetration grade, and imparts characteristics such as greater resistance to heat and improved stability in humid environments.

3. Blending or Mixing Process

At this stage, the manufacturers combine bitumen derived from previous processes with additives or other types of bitumen to achieve the desired final properties.

What is refinery bitumen mixing process? To adjust the penetration grade, bitumen manufacturers blend heavier or lighter bitumen. Additionally, they use polymers, resins, acids, and other additives to enhance bitumen’s elasticity, adhesion, thermal resistance, and overall stability.

4. Other Stages in Refinery Bitumen Production

In addition to the three main processes mentioned above, there are several auxiliary stages that can optimise the production of refinery bitumen:

- Thermal Stabilisation: In some cases, bitumen manufacturers apply final heating to stabilise bitumen’s chemical properties and minimise its unwanted reactions.

- Removal of Water and Light Gases: Moisture and trapped gases are eliminated to enhance bitumen’s storage stability.

- Final Purification: Bitumen manufacturers use specialised filters to remove solid impurities or heterogeneous materials, ensuring uniformity in the final product.

What is Refinery Bitumen and Its Main Characteristics?

Refinery bitumen has important properties such as softening point, ductility, high purity, low weight loss, and appropriate viscosity, all of which ensure its optimal performance in road construction and waterproofing applications.

As an important engineering material, refinery bitumen must be carefully evaluated in terms of its physical and chemical properties to ensure optimal performance across various applications.

1. Softening Point

On the topic of what is refinery bitumen, the softening point is an important trait. This property indicates the temperature at which bitumen changes from a solid to a soft and sticky state. A higher softening point reflects the bitumen’s resistance to deformation in hot weather, which is especially important for use in warm climates.

2. Ductility

Ductility is bitumen’s ability to stretch without breaking at a specific temperature (usually 25°C). Higher ductility means greater flexibility, which minimises the risk of bitumen cracking.

3. Purity Level

Purity refers to the percentage of the bitumen material compared to its insoluble impurities such as soil, minerals, and heavy metals.

High-quality refinery bitumen should have a purity level above 99%. The presence of impurities can affect its adhesion properties, thermal stability, and overall performance.

4. Weight Loss

In defining what refinery bitumen is, weight loss is also an important factor. Weight loss refers to the amount of evaporation or mass reduction of bitumen when heated at a constant temperature (usually 163°C) over a specified time. Therefore, this parameter indicates the thermal stability of the bitumen.

5. Flash Point

What is refinery bitumen flash point? Bitumen’s flash point is the lowest temperature at which its vapours ignite when exposed to a flame source. For road construction bitumen, the flash point is typically required to be above 230°C.

6. Penetration Grade

The penetration grade determines the hardness or softness of bitumen. This is measured by inserting a standard needle into the bitumen at 25°C under a specified load for 5 seconds. Softer bitumen has higher penetration values, indicating greater pliability.

7. Viscosity

The resistance of bitumen to flow, spreading, and handling is its viscosity. This trait is especially important at high temperatures and should be at a level that allows proper distribution of bitumen during asphalt paving operations.

What is Refinery Bitumen and Its Applications?

As the final product of heavy oil refining, refinery bitumen is a material with unique properties such as high adhesion, water resistance, thermal stability, and weather resistance.

Its key applications include road construction, waterproofing, the production of coating and sealing products, and as a raw material in chemical industries.

1. Road Construction

Bitumen is the primary binder used in the production of hot mix and cold mix asphalt. In this application, the engineers combine and road workers combine bitumen with aggregates to form a durable layer resistant to vehicle pressure, freezing, heat, and abrasion.

2. Waterproofing

What is refinery bitumen waterproofing? Bitumen is one of the best waterproofing materials for roofs, foundations, tanks, pipelines, and basement walls. Pre-fabricated insulation products such as membrane sheets (e.g., Isogam) are also made using blown or modified bitumen.

3. Production of Coating and Sealing Products

Bitumen serves as the base material for various coating products such as waterproof paints, primers, industrial adhesives, and asphalt sealants.

4. Raw Material for Chemical Industries

Bitumen is applicable as a raw material in the production of specialised chemicals such as activated carbon, refinery coke, and bituminous resins.

What are the Features and Advantages of Refinery Bitumen?

Key features of refinery bitumen include high adhesion, water resistance, thermal stability, flexibility across various temperatures, and the ability to be modified with polymers.

These properties make refinery bitumen an ideal choice for road construction, waterproofing, and the production of industrial products.

Environmental Benefits of Purchasing Refinery Bitumen from Refineries

What is refinery bitumen’s environmental benefit? Buying refinery bitumen directly from authorised refineries offers significant environmental advantages.

These include reduced emissions from non-standard processing methods, elimination of unauthorised intermediaries who may supply contaminated or recycled bitumen, and assurance that industrial waste is managed in compliance with environmental regulations.

Factors Affecting the Price of Refinery Bitumen

What are the key factors that influence the price of refinery bitumen? The price of refinery bitumen is determined by several factors, including:

- Global crude oil prices (as the primary raw material)

- Type and grade of bitumen (e.g., 60/70 or 85/100)

- Transportation and packaging costs

- Seasonal demand fluctuations

- Export conditions and sanctions

- Currency exchange rate volatility

Best Time to Purchase Refinery Bitumen

Summer and autumn are peak consumption seasons due to the execution of road construction and building projects. During these periods, the price of refinery bitumen tends to rise.

Therefore, the best time to purchase bitumen is usually in late winter and early spring, as demand for construction projects has not yet peaked and prices are relatively lower during this period.

Frequently Asked Questions About What Is Refinery Bitumen

This section addresses common questions related to what refinery bitumen is:

Where Can We Purchase Refinery Bitumen?

Refinery bitumen can be obtained through reputable manufacturers, oil refineries, official distributors, or trusted online sales platforms.

What Factors Influence the Price of Refinery Bitumen?

Factors affecting the price of refinery bitumen include its purity level, global crude oil prices, transportation costs, and supply and demand conditions in the market.

What Are the Characteristics of Refinery Bitumen?

What is refinery bitumen’s important trait? Key characteristics of refinery bitumen include its precise production process and the use of pure raw materials, which makes it highly resistant to various weather conditions.

sources: wikipedia

Bitumen Price

- What Is LPG: Properties + Uses Liquefied Petroleum Gas

- What Is Petroleum Paraffin: Types + Properties And Applications

- What is Petroleum Coke: Types + Applications

- What Is Mazut: Advantages, Applications + Hazards

- What Is Diesel fuel: Types Gas oil + Applications

- What is gasoline? Types + Uses and Production Process